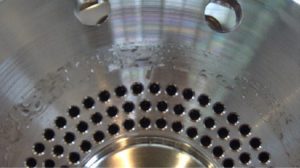

It is a chemical surface treatment made from a Nickel-Phosphorus alloy (86% nickel, 14% phosphorus). The reaction occurs spontaneously without the use of current, in this way it is possible to obtain an extremely uniform thickness of coating which avoids the subsequent adjustment to the deposition, regardless of the geometry of the workpiece. The chemical nickel, contrary to electrolyte nickel and hard chrome, is not subject to peak effects and also perfectly covers internal areas such as holes, threads or cavity.

MetalenP – Certified NSF

What is the chemical nickel MetalenP Certified NSF?

Which materials can we nickel plate?

With the MetalenP chemical nickel plating treatment, Certified NSF, it is possible to coat practically any material. Specifically, the Metalcoating performs coatings on: ALLOYS OF CARBON STEEL, SINTERED, COPPER, BRASS AND BRONZE.

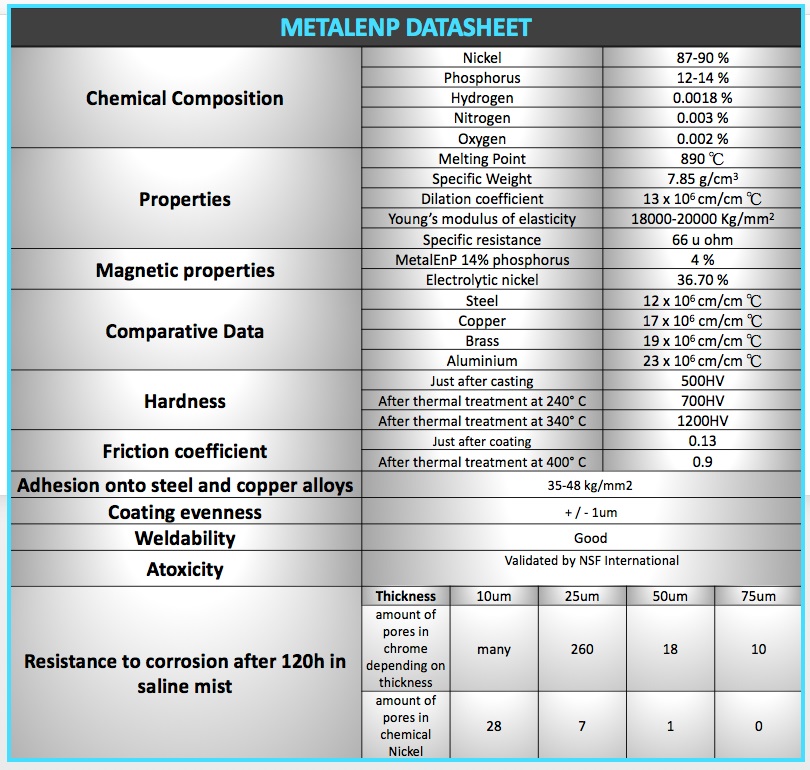

Coating characteristics

Endurance and resistance to wear

A chemical nickel deposit has a hardness of 500-550 HV (52HRC), already equal to the best hardened steels. It is possible to increase the hardness by performing a heat treatment (annealing) of the workpiece coated at a temperature of 400 ° C for 1 hour or at 300 ° C for 12 hours, obtaining a hardness of up to 1200 HV (72 HRC), the upper value to those reached with chrome plating. The heat treatment helps to increase the wear resistance, bringing it to values equal to those of chrome.

Corrosion resistance

One of the main characteristics of the MetalenP Certified NSF, treatment is the high resistance to corrosion. A chemical nickel coating, which has a very low porosity, completely seals the base material, protecting it from corrosion. The percentage of the phosphorus present in the alloy is of fundamental importance. In fact, at high phosphorus levels (above 10%), the coating exhibits the best corrosion resistance.

Adhesion

The adhesion of the coating to the base material is excellent (45 Kg / mm2) and higher than that of chrome.

Friction Coefficient

The friction coefficient, thanks to the self-lubricating power of the phosphorus, is low, particularly as a result of annealing.

Non-toxicity (REACh & RoHS) - Food contact (Certified NSF/ANSI 51)

The MetalenP Certified NSF treatment, thanks to its high resistance to corrosion, ensures non-toxicity.

No heavy metals are used, and its formulation fully respects everything that is cited in the requirements of Reach (there are no SVHC at levels exceeding 0.1% by weight) and RoHs2 (there are no substances of restricted use above the maximum concentrations tolerated) it is also fully certified by the American body NSF (with annual review) and therefore can be used in the food and beverage industry.

What are the main reasons that lead to such a widespread use of the chemical nickel MetalenP Certified NSF treatment ?:

- The uniqueness of the deposition method used to coat every piece in its entirety and in a uniform manner.

- The good resistance to corrosion, in the majority of aggressive environments, which offers the possibility of replacing stainless steel, expensive and difficult to machine, with the most economical steel coated carbon.

- The possibility of coating materials of lower hardness but more easy to work mechanically.

- The possibility of obtaining levels of hardness well in excess of those attainable with the hardening of steel treatments (hardening, carburizing, gaseous and ionic nitriding, etc.) or with other surface treatments.

- The reduction of friction and the consequent increase in the life of the parts.

- The possibility of recovering worn parts, even for complex shapes (for example: moulds, gears, etc.), back into their original dimensions.

- The possibility of giving an excellent aesthetic appearance.

Applications for the MetalenP Certified NSF treatment:

As we have said it is easy to understand that the chemical nickel plating is suitable for applications in every industry, and principally for:

AUTOMOTIVE

AEROSPACE

DIES FOR PLASTICS AND NON-PLASTICS

MINING

PETROCHEMICAL

MARINE INDUSTRY

LIGHT, HEAVY AND PRECISION MACHINARY

TEXTILE

CHAINS

CHEMICAL INDUSTRY

HYDRAULIC

PNEUMATICA

MEDICAL

ELECTRONICS

ARMS INDUSTRY

FOOD & BEVERAGE (NSF)

SOME USEFUL INFORMATION BEFORE ACCESSING THE TREATMENT OF CHEMICAL NICKEL PLATING:

The chemical nickel coating can be run either on small parts, with work on barrel plating, or on larger materials using frames. (Measurements max 1,350 mm height, 1,850 mm length, 750 mm width).

The standard coatings range from a minimum of 5 μm to a maximum of 50 μm, but we can also evaluate different requests.

On special request we can also perform within our company; sand blasting and shot peening treatments, protection or masking.

For the best results, the part should be provided free of impurities and oily residues, it should not be magnetic, and it should not be assembled and composed of different metals.

FOR FURTHER DETAILS PLEASE VISIT THE FAQ PAGE. CLICK HERE