OUR LABORATORY IS EQUIPPED WITH VARIOUS EQUIPMENT AND CAN MEET VARIOUS REQUIREMENTS OF CHEMICAL ANALYSIS AND METALLOGRAPHIC ANALYSIS.

FOR THE SELECTED INSTRUMENT, WE ILLUSTRATE THE FEATURES IN DETAIL, THE OPERABLE FUNCTIONALITY AND ANALYSIS, IN COLLABORATION WITH Tecnologie Superficiali Srl.

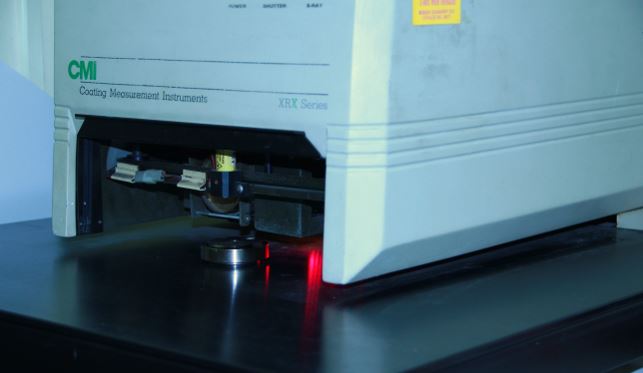

THICKNESS GAUGE

What is a thickness gauge and what is it used for?

The Oxford CMI 900 thickness gauge, which is fitted to our metallographic laboratory, is a tool designed to measure the thickness and/or the chemical composition of coatings and films.

What can we analyse at Metalcoating?

- Measurement of thicknesses of coatings on multilayer samples

- Chemical analysis

- Analysis of galvanic beads

- Measurement of carat gildings

- Analysis of electronic components

- Analysis of galvanic tanks

- evaluation of custom layers (possibility to acquire calibrators in accordance with the customer)

Characteristics of the instrument

- Reveals thicknesses and coatings constituted by chemical elements with an atomic weight greater than Titanium (> 22):

- instrument complies with ISO 3487, ASTM B568 and DIN 50987;

- Sample positioning repeatability and repeated measurements (independent of the operator)

- Automated pointing to the array of X-ray laser (laser is positioned about 1.3 cm from the focal plane);

- automatic scanning along the vertical z axis for obtaining the optimal distance of the sample from the excitation system and detection;

Principle of operation

The CMI 900 Oxford uses ED XRF analytical technique for the measurement and analysis of coatings. It is equipped with an X-ray tube that is directed towards the appropriately positioned sample; a detector of X-rays detects the presence and composition of the elements. The intensity of the light “X” emitted by the sample is proportional to the thickness and/or the chemical composition of the sample.

The CMI 900 uses the calibration method FP (Fundamental Parameters) optimized. This analytical method uses the physical principles applied to items under consideration and to the hardware features of the excitation and detection.

The FP software installed in the instrument, calculates the coating thickness and the chemical composition of the sample.

The advantages of this method can be summarized as follows:

- Ease of calibration:

- The FP calibration covers a wide range of thicknesses, including multi-layer applications;

- Our laboratory can then test a wide variety of samples.

- Calibration standards unnecessary;

- Standards are not always available with the same matrix of the sample to be analysed;

- When there is a limited number standard, FP calibration is a reliable means for quantitative analysis.

- The elements, pure components, layers and base, and one or more known Oxford standards are required. A single sample is sufficient in most cases

With CMI900 you can create semi-empirical calibrations using known thickness standards included in the FP method.

These can be in possession of the customer or, alternatively, bought from Oxford Instruments.

The accuracy of quantitative measures is closely linked to the quality of standards used for calibration.

The semi-empirical method, constructed with at least one certified standard, provides the best performance.