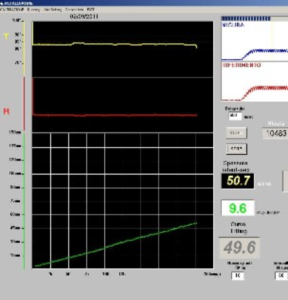

Based on over 25 years of technological expertise, Micronmeter is the result of a long project devoted entirely to the research, development and production of a high-quality instrument to measure in “real time” the thickness of the coating layer in the industry of metal surface treatments.

Micronmeter has led the way with a technology that can meet the growing demands for a viable and important industry such as this. Using our skills, we have employed and implemented the best available technology solutions, remaining constantly engaged in order to make a difference for both for our customers and the environment.

Your investment in our equipment represents our goal of providing comprehensive support to ensure your success.

Micronmeter is a registered trademark of Tecnologie Superficiali Srl.